30 tammi Activities of the Gut Health and Fermentation Platform (GHFP)

New platforms, such as the Gut Health and Fermentation Platform (GHFP), are being build upon regional specialization as well as national and international know-how during Food Valley project (2018 – 2020). The GHFP is for studying existing and new probiotics, prebiotics and other functional foods and ingredients, their identification, safety and availability and related technologies. Investigating digestion and relationships between food items and other ingredients with the host and the gut microbiota will also be possible with a gut model that mimics the physiology in stomach and small and large intestine. This article tells more about the activities of the GHFP presented in Food Valley’s newsletter of January 2020.

During autumn 2019, Food Valley’s Gut Health and Fermentation Platform has been using 16S sequencing analysis for strain identification and microbial communities, evaluating optimal lyophilization conditions in different probiotic strains and survival tests as well as started the first tests in the bioreactor. These activities have also made it possible to continue the active collaboration with Food Valley project companies.

16S sequencing analysis for strain identification and microbial communities

The Gut Health and Fermentation Platform (GHFP) has been evaluating different DNA extraction kits for microbial samples (pure strains, food, fecal samples) and methods to quantify the extracted DNA. Samples have been provided by a food technology company Probitat Oy.

Now we count with reliable methods to extract and quantify DNA that can be used for molecular analysis. Sequencing services may be purchased from different places. Our recent experience includes the FISABIO Sequencing and Bioinformatics Service, in Valencia (Spain), and Novogene. In our platform, we count with the experience for proper interpretation of the data and subsequent statistical analysis.

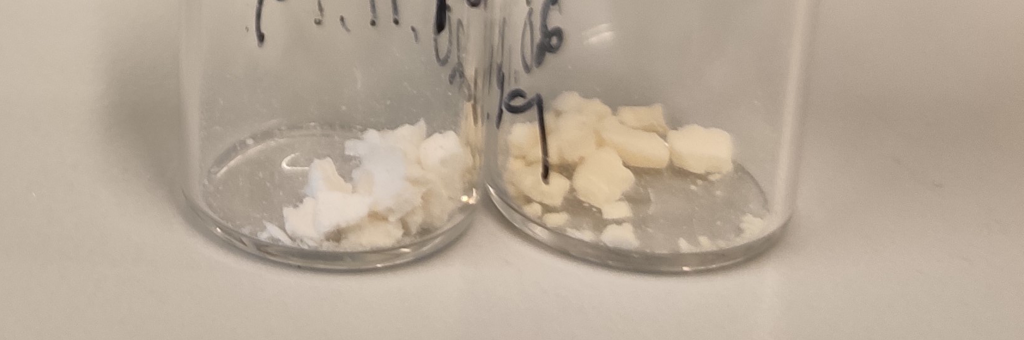

Evaluation of optimal lyophilization conditions in different probiotic strains and survival test

Freeze-drying, also known as lyophilization, is a widely used process for handling samples to ensure the maintenance of product stability and quality criteria during shipment and storage. This process can be applied to bioactive compounds (or a mix of them) and microbes (probiotics) to increase their stability.

In collaboration with the Pharmacy Department of University of Eastern Finland and SME- know-how company Innolact Oy, we have been testing the resistance of different bacterial strains to freeze-drying with a microscale freeze-drying approach, similar to the method described by Peters and collaborators in 2014.

Aspect of different probiotic strain after microscale freeze-drying

To test the survival of the different bacterial strains in a microscale approach allows to reduce time and resources. The probiotics presenting better survival can be used for production on a big scale, lyophilization and later use as supplements in food formulations.

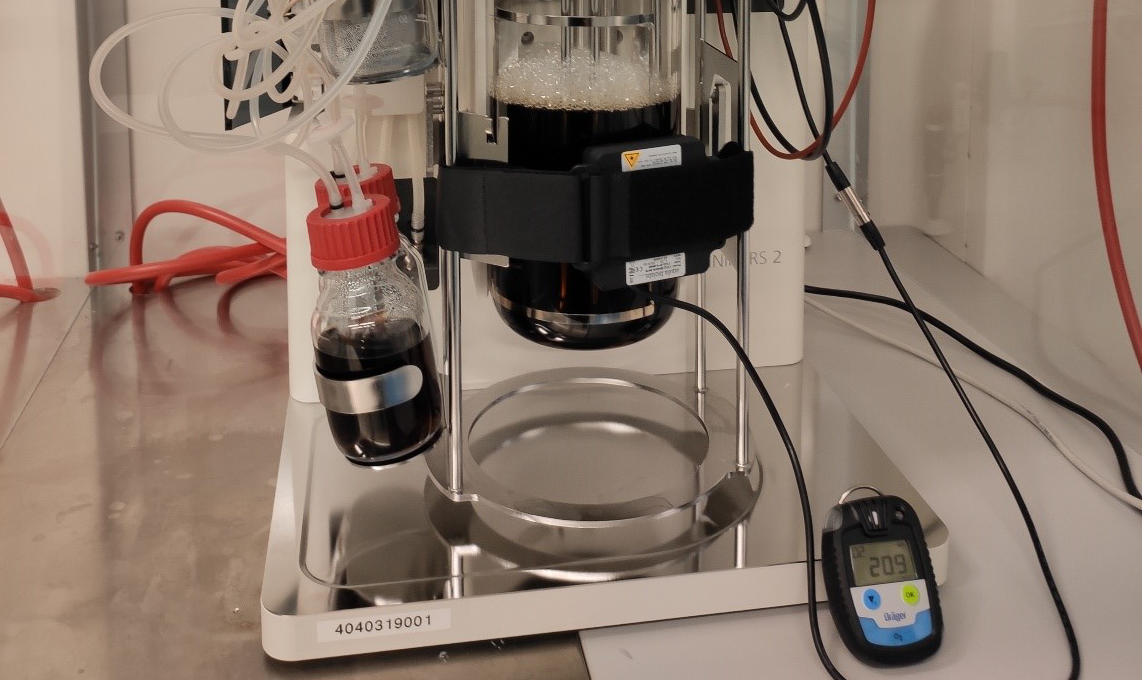

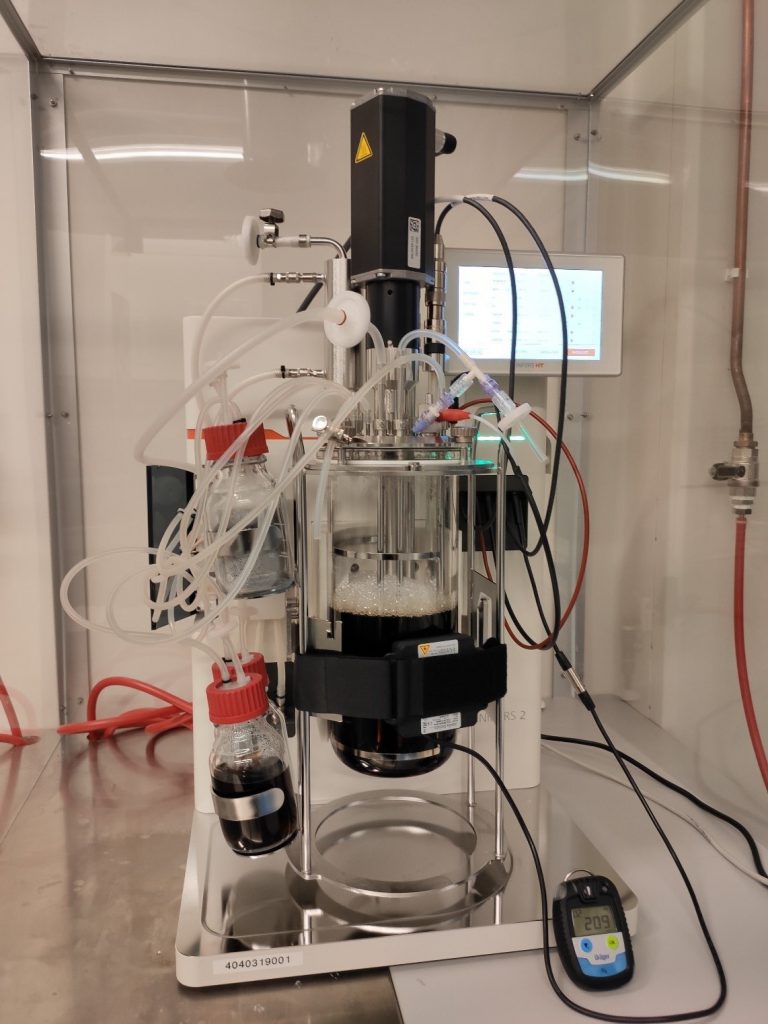

Bioreactor working at UEF

The bioreactor is running!

The first tests in our bioreactor for colonic fermentation have already started. We have been checking the different basic functions of the equipment. Our devices can provide everything needed to mimic the colonic environment and be used to develop the in vitro method for testing the impact of food constituents on intestinal microbiota composition and activity.

During the following weeks, we will be focusing in more complex functions, including monitoring of microbial dynamics with the biomass sensor.